WLD-UV2513 UV FLATBED PRINTER apply Skeleton triangle welding technology, nozzle collision protection, Bi-direction printing technology, "cellular" adsorption platform, water cooling system.

Can be equipment with Ricoh G5 7 picoliter nozzle

Gray scale all steel piezoelectric nozzle

Variable ink drop minimum 7PL, maximum 35PL

High speed and high precision

Normal service life of up to 3 years

Industrial nozzles

Colorful white varnish can be ejected at the same time

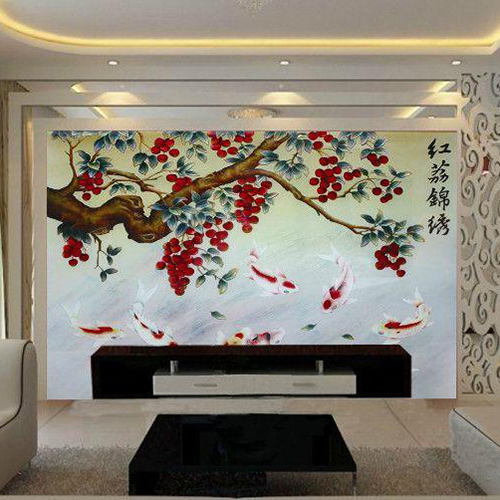

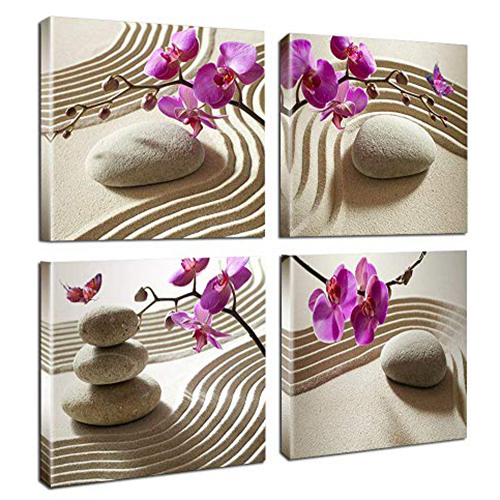

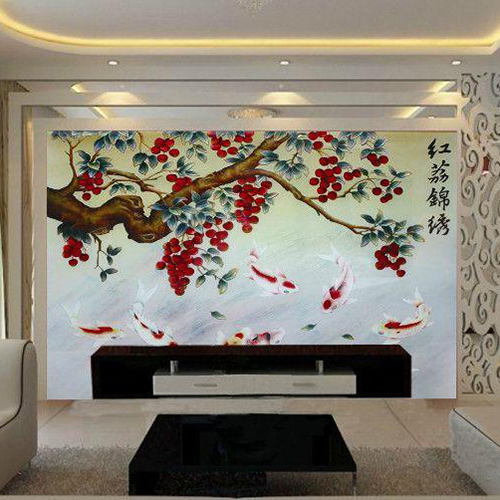

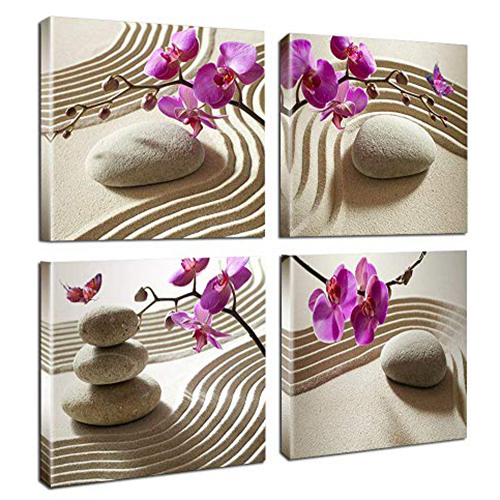

Can print out special effects directly Embossed effect, gold color printing, silver color printing, 3D effect, 4D effect, local varnish

Oman Ahmed 968 *** 9390 EPS-WLD-UV6090 11/14/2018

Oman Ahmed 968 *** 9390 EPS-WLD-UV6090 11/14/2018  Australia Martin 0416 *** 775 EPS-WLD-UV4590 09/18/2018

Australia Martin 0416 *** 775 EPS-WLD-UV4590 09/18/2018  Australia Peter 7 3*** 4652 EPS-WLD-UV2232 11/20/2018

Australia Peter 7 3*** 4652 EPS-WLD-UV2232 11/20/2018  Colombia Hernán Ro*** 322***2715 WLD-UV3040 09/25/2018

Colombia Hernán Ro*** 322***2715 WLD-UV3040 09/25/2018  India Ankur Gu*** 098***8829 WLD-UV2513 11/26/2018

India Ankur Gu*** 098***8829 WLD-UV2513 11/26/2018  HongKong Daniel W*** 852 *** 6408 WLD-UV2232 11/29/2018

HongKong Daniel W*** 852 *** 6408 WLD-UV2232 11/29/2018  Ukraine com***tion LLC 380-9***1720 WLD-UV1325 11/30/2018

Ukraine com***tion LLC 380-9***1720 WLD-UV1325 11/30/2018  USA Adam R*** '+173***0151 WLD-UV1313 12/12/2018

USA Adam R*** '+173***0151 WLD-UV1313 12/12/2018  Mongolia DUDU*** 976-***9350 WLD-UV6090 Cylinder Print 12/15/2018

Mongolia DUDU*** 976-***9350 WLD-UV6090 Cylinder Print 12/15/2018  Ecuador Mr. MARCELO M*** 593-***9195 WLD-UV4590 Cylinder Print 12/26/2018

Ecuador Mr. MARCELO M*** 593-***9195 WLD-UV4590 Cylinder Print 12/26/2018  Ecuador Mr. Romeo N*** 593-***3024 G-WLD-UV3040 12/17/2018

Ecuador Mr. Romeo N*** 593-***3024 G-WLD-UV3040 12/17/2018  Switzerland Ella M*** 41-453-***8764 WLD-UV6090 12/18/2018

Switzerland Ella M*** 41-453-***8764 WLD-UV6090 12/18/2018  Switzerland Karl Fri*** 41-5***3211 WLD-UV2513 12/18/2018

Switzerland Karl Fri*** 41-5***3211 WLD-UV2513 12/18/2018  USA Mrs. Happi N*** 1-973***5711 WLD-UV1313 12/19/2018

USA Mrs. Happi N*** 1-973***5711 WLD-UV1313 12/19/2018

Large lifting range, small head is stable, beam accuracy is 0.01

The use of electronic anti-collision system, the nozzle anti-collision has played an effective role in protection, reducing the damage rate of the noz

The partial block adjusts the suction area, and the air volume is adjustable. Ensure the tolerance of different materials to suction. The surface of t

| Model Type | WLD-UV2536 | |||

| Nozzle configuration | Ricoh GEN5 1-8 GH2220 industrial nozzle 1-16 Japan epson micro piezoelectric nozzle 1-2 | |||

| Maximum print size | 2500mm×3600mm/8*12' | |||

| Print speed | Ricoh:Four nozzles | sketch model 48m2/H | production 25m2/h | High quality pattern16m2/h |

| Epson:Two nozzles | sketch model 10m2/H | production 6m2/h | High quality pattern3m2/h | |

| Print material | Type:Acrylic, aluminum plastic board, wood, tile, foam board, metal plate, glass, cardboard and other plane objects | |||

| Thickness: 0 mm - 120 mm/0-5" | Uniform weight: 25kg | Maximum size: 2500mm x 3600mm/8*12' | ||

| Ink type | Blue, magenta, yellow, black, light blue, light red, white, light oil | |||

| The UV lamp | Ricoh:LED-UV | Two:1500W | life:20000-30000 hours | compression refrigeration cooling |

| Epson:LED-UV | Two:420W | life:20000-30000 hours | water cooling | |

| RIP software | PhotoPrint,Monteiro,Ultraprint;Microsoft Windows2000/XP/WIN7 | |||

| Power supply voltage,power | AC220v, hosts the largest 1650 w, LED - the UV lamp's largest 200-1500 w, 1500Wx2 vacuum adsorption platform | |||

| Image format | Tiff,JEPG,Postscript3,EPS,PDF Etc. | |||

| Color control | Comply with ICC standard, have curve and density adjustment function. | |||

| Print resolution | 720*360dpi,720*720dpi,360*1080dpi,720*1080dpi,720*1440dpi,1440*1440dpi | |||

| Operating environment | Temperature: 20 ℃ to 28 ℃ humidity: 40% to 60% | |||

| Apply the ink | Ricoh and LED-UV ink, solvent ink, textile ink | |||

| The machine size | L 4260mm X W 4050mm X H 1500mm | |||

| Packing size | L 4360mm X W 4210mm X H 1650mm | |||

Sectional Vacuum System

This flatbed printer is designed with an adjustable air flow inside the vacuum system, based on the tolerance levels of different materials. The entire system is flat, corrosion resistant and features a uniform vacuum force.

Butt Welding Technology

Thanks to butt welding technology, the machine frame is strong, preventing deformation, even under extreme temperatures and rough transportation, as well as operating stress.

High-Precision lead screw

The printer is also equipped with a high precision lead screw to ensure precise location, as well as ensure ink is ejected into the correct location without any errors.

Industrial rail

HIWIN brand rail with high duration and great precision. Option of THK industrial rail is available.

Water cooling system

With Ricoh compressed water cooling technology, the machine has a good heat dissipation and the Led is of long service time.

Imported Led Lights

Due to the use of an advanced LED-UV curing technology, our UV flatbed printers require no preheating, and are capable of operation as soon as they are turned on. Further, the low-heat consumption of the LED-UV lamps feature a service life of 20,000-30,000 hours under normal operation, reducing additional lamp replacement costs.

Commercial UV Printing Machine, Wide Format Color Printer, UV Digital Printer.

WLD-UV2536 UV Flatbed Printer is suitable for applications such as advertising, glass processing, house decoration, furniture manufacture, handicraft processing, leather printing, packaging and printing, mobile phone shell, toy, accessories, etc.

| No. | Item | Unit | Discription | Warranty | Function | Price |

| 1 | Printhead | Pcs | No | |||

| 2 | Jet board 8 heads | Pcs | No | |||

| 3 | Mainboard 8 heads | Pcs | No | |||

| 4 | Nozzle transfer board With line |

Pcs | No | |||

| 5 | 150 Grating belt | Pcs | No | |||

| 6 | 150 Grating reading head | Pcs | No | |||

| 7 | Safety bottle | Pcs | No | |||

| 8 | Secondary ink bottle | Pcs | No | |||

| 9 | Big filter | Pcs | No | |||

| 10 | Heater strip | Pcs | No | |||

| 11 | Magnetic valve | Pcs | No | |||

| 12 | Negative pressure display list |

Pcs | No | |||

| 13 | Optical fiber (10m) |

M | No | |||

| 14 | 7W Ink pump | Pcs | No | |||

| 15 | Negative pressure control panel |

Pcs | No | |||

| 16 | Pressure sensor | Pcs | No | |||

| 17 | White ink stir motor | Pcs | No | |||

| 18 | Power supply | Pcs | No | |||

| 19 | Air-switch | Pcs | No | |||

| 20 | Relay | Pcs | 220V | No | ||

| 21 | Common relay | Pcs | 24V | No | ||

| 22 | Z-axis motor | Pcs | No | |||

| 23 | Z-axis driver | Pcs | No | |||

| 24 | Origin inductor | Pcs | No | |||

| 25 | Belt | Pcs | No | |||

| 26 | TP02 the inductor | Pcs | No | |||

| 27 | Front and back Proximity switch | Pcs | No | |||

| 28 | 400W Motor | Pcs | No | |||

| 29 | 400W Driver | Pcs | No | |||

| 30 | Led lamp | Pcs | No | |||

| 31 | Heating controller | Pcs | No |

Price description

For the above items, there are some consumable parts and some Non vulnerable parts, if you need the exact price, please feel free to contact our sales.

Attention

If you have bought our company printers, in order to avoid the printhead and the mainboard damage because of some wrong operation, you should install the printhead correctly in operation and maintenance according to the following way. And refer to the instructions, or under the guidance of the professional engineers operation.

1. Clean and lubricity of guide screw and bearing (3 days)

①.Lubricating grease to ensure that the screw guide clean and lubricity

②.Spray car bearing to keep clean

2. Print heads prior to shutdown state diagram to ensure that the state of the nozzle is normal

3. Closed software, automatic spray car back to protect wet, then turn the power off, keep the car in moisture

4. Boot before every day with a clean cotton swab swab wet special cleaning fluid ink pads and doctor blade, prevent ink drying into pieces, residue on it.

5. Regular cleaning platform redundant ink printing machine work

6. Every print heads before starting the state diagram, maintain nozzle working properly

7. Regularly clean excess ink from the mirror surface of the uv lamp to maintain the curing effect of the uv lamp. Air-cooled heat-dissipating dust and flying ink on the air outlet of the fan and UV lamp (5-7 days) to clean the fan and keep the fan cool. Water cooling should pay attention to the water circulation. The antifreeze should be replaced once a month to keep the antifreeze clean and free of sediment.